The best energy solutions on the market

INDUSTRIAL GENERATORS

THE 10 KEY POINTS WHICH MAKE THE DIFFERENCE

6kVA – 830kVA

5kW – 750 kW | 50 HZ – 60 HZ

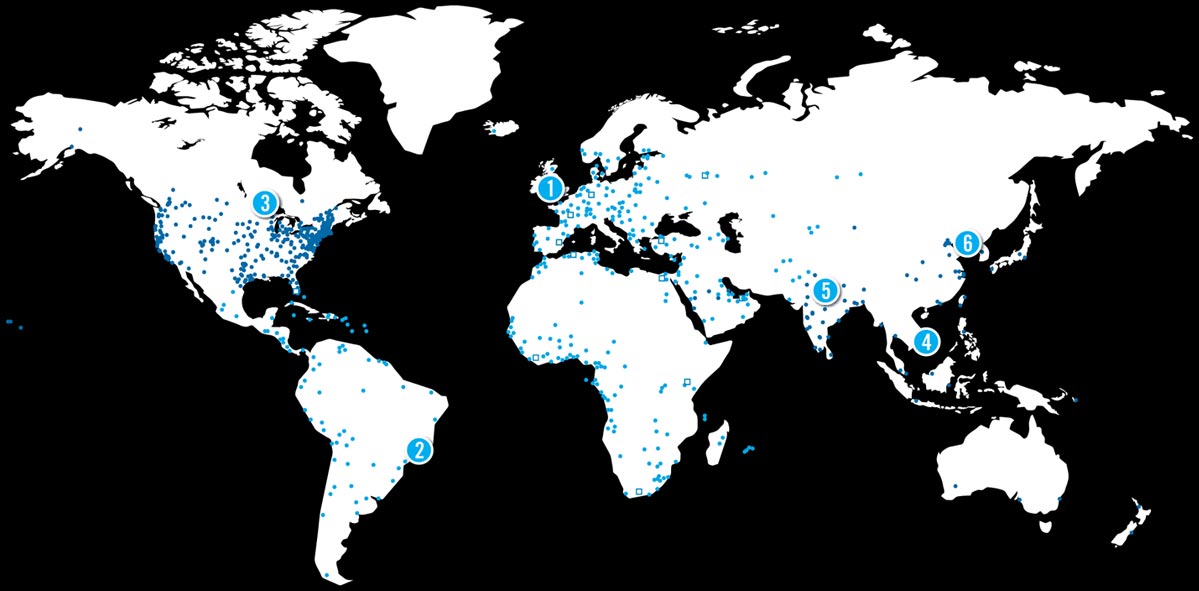

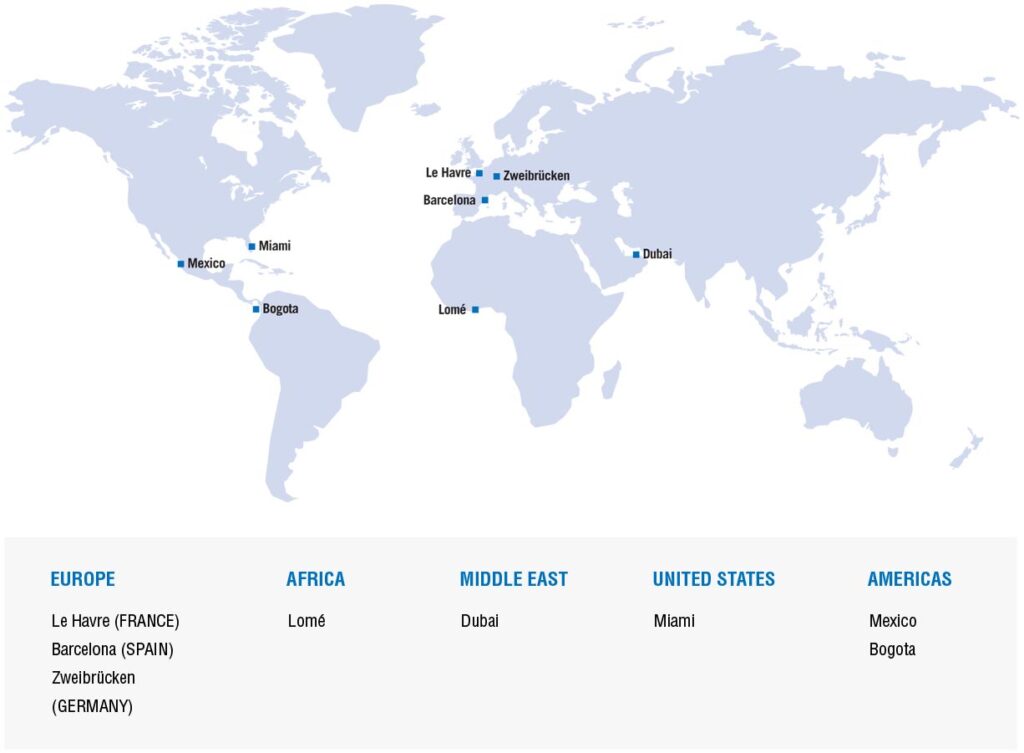

International Coverage

Think globally, act locally – with sites exactly where you need them.

In France

Worldwide

A HIGH LEVEL OF SERVICE

AVAILABLE ALL OVER THE GLOBE

The Kohler Service department offers you the best possible support to maximize the performance of your generator whilst minimizing its operating costs.

Expert Assistance

Right where you need it

A Rapid Response to Your Requirements

Skills Training With our Experts

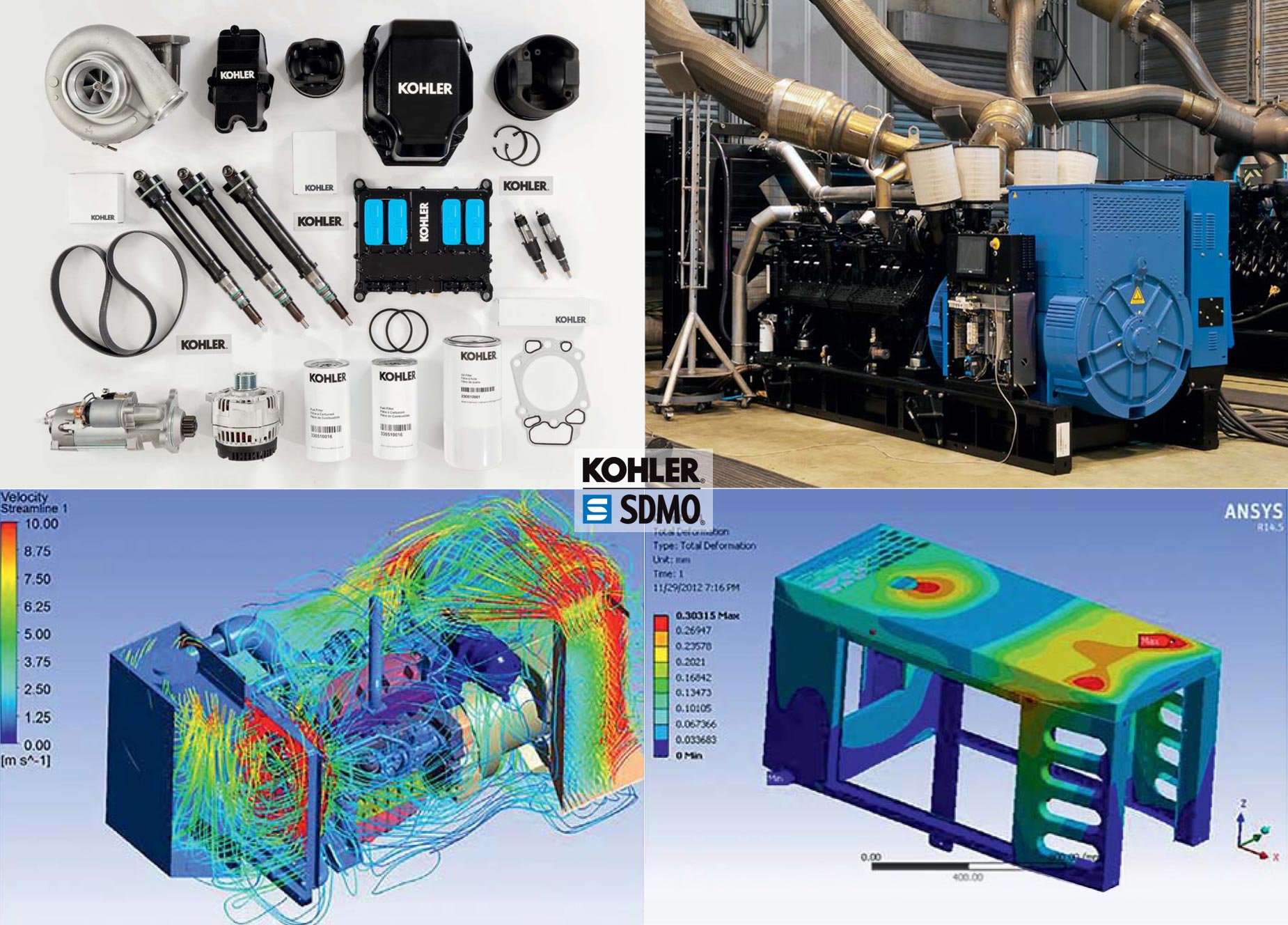

High Quality Spare Parts & Consumables

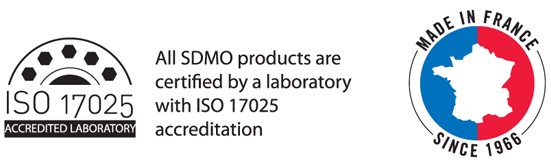

An Integrated R&D Function

Design office

Using the latest technical innovations

A Cutting Edge Laboratory

Modern Fully Certified Factories

The 10 Key Points Which Make The Difference

Access the Highest Level of Performance

Optimised Sound Level

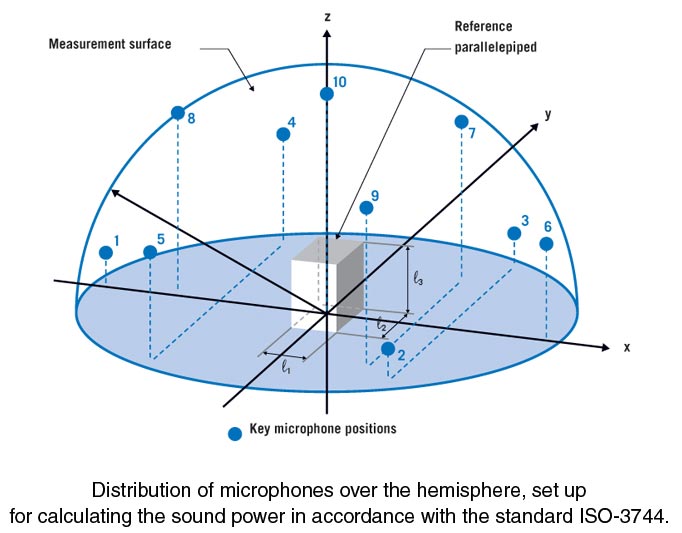

Noise reduction is a non-negotiable priority for Kohler. As a company, we are fully subscribed to a policy of combating noise outside the building enclosure: in line with the European standard relating to sound levels, we perform regular checks on our standard product ranges to ensure they comply with the most stringent of standards.

Important Information

The sound level of a generator can be expressed in one of several ways:

- in Lwa

- in dB(A) 1m

- in dB(A) 7m…

The sound power, expressed in Lwa, is the power from a sound source transmitted into the surrounding environment in the form of airborne noise. For generators, the sound power is measured on a generator operating at 75% of its rated output at 50 Hz, and at 100% at 60 Hz.

The sound pressure, expressed in dB(A), corresponds to the unit of measurement for the sound level. It depends on the distance from the sound source and on several other criteria, relating to the characteristics of the space itself.

KOHLER-SDMO, however, goes way beyond the conventional measuring tools needed to check the soundproofing of its generators.

| The Criteria | Standard Method | Added Kohlerv Benefits |

|---|---|---|

| SOUND LEVEL MEASUREMENT OF MACHINES AND INFORMATION ON THE OVERALL SOUND PRESSURE | A sonometer or several microphones linked to an acquisition system measure the sound level in db(A). | Sound intensity: a spectrum of the sound emitted by the various components, this measurement enables identification of not only the emergence of noise in dB(A), but also via the frequency band in Lwa. It enables sound sources to be located precisely, and their intensity determined, allowing the generator’s soundproofing to be optimized. |

| THE QUALITY OF MEASUREMENTS | Sworn declarations | A laboratory accredited by COFRAC (the official accreditation body within France) Measurements certified by CETIM (the technical center for the mechanical industries), which audits Kohler each year, validating its measurement facilities, its equipment, its procedures, and the accuracy of the measurements it takes. |

| THE RELIABILITY OF MEASUREMENTS | Tests performed on a single generator | Guaranteed sound value, based on the average of measurements taken on 10 identical generators, to which a statistical correction is made |

Complete control of sound levels is an especially important criteria for installations in urban environments (hospitals, nursing homes, shopping centers, and so on).

Reliable Power

Even in Extreme Conditions

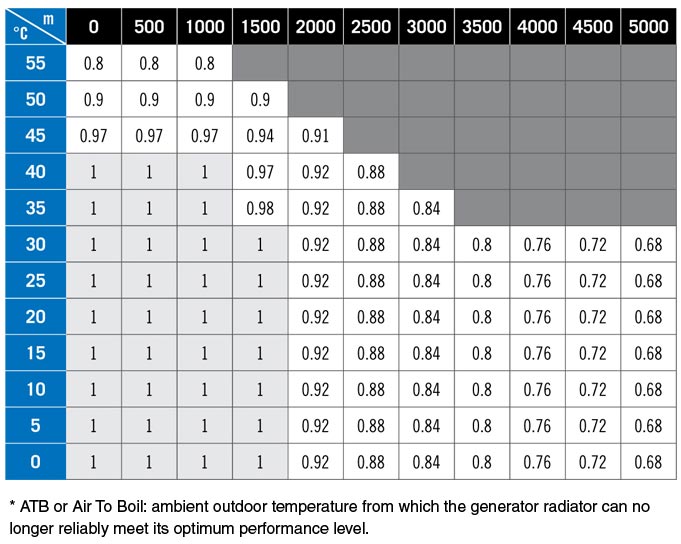

Cooling is a key factor when it comes to choosing a generator. An effective cooling system enables the generator to maintain its rated output, even under difficult or even extreme – conditions, where the ambient temperature is very high.

The quality of the engine, the design of its enclosure, and the coolant system itself, all affect the ATB* level of a generator. The Kohler engineering department ensures that cooling systems are perfectly adapted, allowing the best possible ATB* level to be obtained. The resulting solutions are able to exceed the standards conventionally set in terms of maintaining the maximum output under the most extreme temperatures.

100% engine performance is maintained.

The Kohler design office has developed an automated system for calculating the derating factor for all its generators. This enables a generator’s performance level to be analyzed precisely, based on the geographic considerations (altitude, ambient temperature) applicable to the installation.

KOHLER-SDMO generators in the Power Products industrial range have a minimum ATB level of 40°C in standby mode, and 45°C when used as the prime source. This means that at 40 or 45°C, when some manufacturers cannot supply the cooling needed for their generators to run at full power, KOHLER-SDMO generators deliver 100% of their capacity, without a drop in power.

The ATB* level is a decisive factor in areas where temperatures are high (Middle East, Africa) for applications which need generators to be running at their full capacity at all times.

Having a cooling system which guarantees a good ATB level enables the installation to be sized very accurately to ensure it provides the exact output needed. There is no point choosing a generator which provides more power than needed. For example, if an application needs 200 kW at 40°C, Kohler can offer 200 kW generators which provide the required output, whereas some generator manufacturers will have to suggest a 230 or even 250 kW model, as the capacities their models offer degrades as the temperature increases.

Example on a V400C2 generator

In temperatures up to 40°C and an altitude of 1000 m, the coolant system on a Kohler generator enables it to continue running at full capacity. At 45°C, it delivers 97% of its rated output.

Please note: The components selected and the adjustments made by Kohler also allow for operation at full power at high altitudes and in extremely cold conditions.

Full Control of

Fuel Consumption

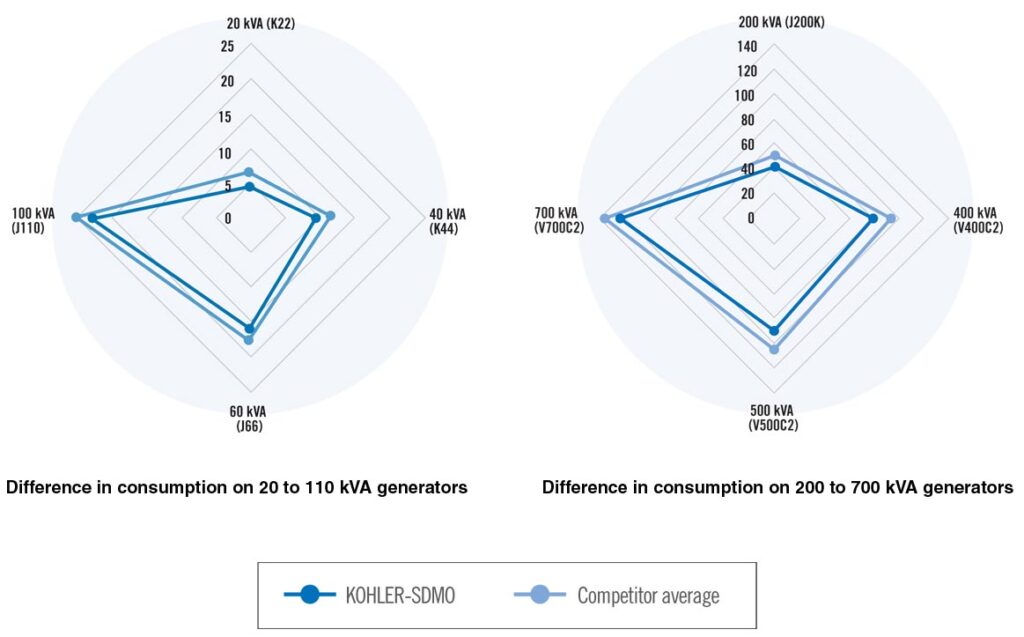

Fuel consumption is a decisive factor when choosing a generator, particularly for production applications which require it to run without any interruptions. This has a direct impact on operating costs, both economic and in terms of the environment.

The consumption of Kohler generators has been optimized from the design stage, with components being selected for the high levels of performance they offer. Furthermore, our engineers and technicians develop specific solutions to further improve this performance.

So, with an equivalent engine, a Kohler generator enables significant fuel savings when compared to generators available from other manufacturers.

Optimizing consumption – even a minimal gain – can lead to significant financial savings in production applications. A generator’s consumption is a determining factor for production applications, particularly in areas where the current is not stable.

Compact Footprint

Big Performance

The footprint of a generator – in terms of both surface area and volume – is key to ensuring its integration, regardless of space constraints. Thanks to their innovative engineering, Kohler generators pack big performance into a compact frame, in both enclosed and open versions.

Kohler Benefits

- Adapted to fit restricted spaces

- Options developed to facilitate connection of the generator

- Number of generators per container optimized for transport

- Reduced transport costs.

Even During Load Surges

Your Activity Can Continue

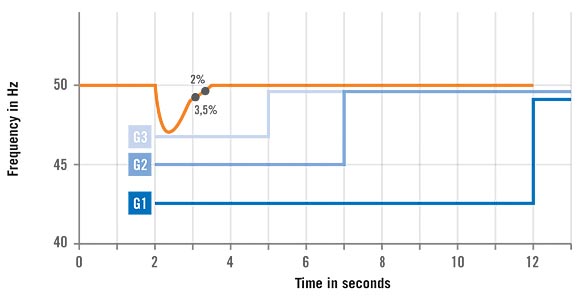

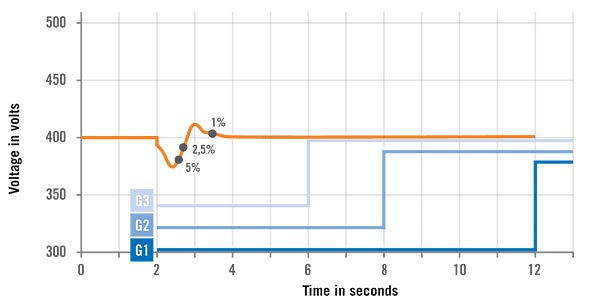

The performance class corresponds to the generator’s ability to absorb load impacts during transient phases, whilst retaining the quality of the electricity produced in terms of frequency and voltage. It is an essential criteria when it comes to preventing a generator from stalling at peak load.

Standard ISO 8528-5 defines three performance classes:

G1, G2 and G3, with G3 being the highest, most stringent category. Kohler places a lot of emphasis on this criterion as it is key to starting up heavyweight machinery with integrated motors, and for critical applications (data centers, hospital equipment, etc.).

KOHLER-SDMO generators are classified G3 either as standard, or by selecting additional equipment available from the list. Contact us for further information.

KOHLER-SDMO BENEFITS

Start-up capacities and optimum load take-up:

- When a generator supplies electric motors, these motors consume up to 8 times the rated current. Thanks to the components selected and adjustments made by Kohler, their generators transmit these start-up currents with a minimal drop in voltage. This is the start-up capacity.

- For installations not containing electric motors, we talk about “on-load capacity”. Here, again, the components selected by Kohler allow for 100% take-up of the load. Their generators reach on-load capacity quickly, and with a minimal drop in voltage, while those from other manufacturers are liable to stall if a high load is requested too suddenly

Enhanced Safety,

Protection Guaranteed

Ensuring people and installations are protected is at the core of the Kohler philosophy. The R&D department works every day to create safety solutions perfect for different markets and applications.

| Concrete Example | Kohler Benefits |

|---|---|

| MANAGEMENT OF NEUTRAL SYSTEMS | Modular management of all neutral systems (TN, TT, IT) installations adapted to the specific needs of each market ability to switch from one system to another with the greatest of ease, ensuring both people and the installation are kept safe eliminates the risk of fire responds quickly to urgent requests |

| CIRCUIT BREAKER QUALITY | for modular circuit breakers up to 125A, Kohler proposes B curve circuit breakers adapted to the generator’s short circuit current, which provide more accurate tripping in the event of a malfunction. for a higher amperage, Kohler uses electronic circuit breakers which enable the thermal and magnetic current to be adjusted more accurately. This adjustment means that it can be adapted to each type of generator, within the advertised rated voltage |

| COUPLED GENERATORS | INNOVATION Toroidal current transformer unit: using the TT neutral system, for coupled generators, this unit ensures the generators are activated in relation to the installation’s fault current. guarantees the safety of persons and property Watt meter control for synchronised generators ensures only the exact number of generators needed to meet the requested current are utilized |

| GENERATOR PREHEATING | Preheating the coolant warms up the engine block, allowing the following: improved start-up capacity at low temperatures immediate application of the load reduction of smoke emissions at start-up Preheating using circulation, available as an option on certain outputs, enables continuous circulation of the coolant to provide uniform heating. the engine’s service life is increased the consumption of electricity for preheating purposes is significantly reduced |

| BATTERY CHARGER | Kohler battery chargers are sized to be used with all battery voltages and currents available on the market. Endurance tests have been conducted by our laboratory to ensure they are robust, and start without fail throughout the generator’s life cycle. |

| INSTRUMENTATION & CONTROL | Specific instrumentation and control units have been developed in-house, adapted to the individual needs of our customers. |

Robust Base Frames

& High Quality Enclosures

The quality of the base frame and enclosure is crucial to ensuring the service life of a generator. A high quality enclosure protects the generator’s components whilst enabling it to run under the most extreme of conditions (high temperatures, dusty or sandy environments, etc.). Kohler selects its base frames and enclosures according to very strict criteria, and they are produced in France.

High Quality Materials

- Enclosure made from European grade electro-galvanized steel

- Base frame with two coats of paint

- Optimized design protecting against corrosion (preventing water ingress and stagnation)

- Highly durable QUALICOAT-certified epoxy paint, specially developed for Kohler

Tests

- Enclosure and base frame monitored and tested by the French Corrosion Institute, enclosure with a guaranteed 500 hours of resistance to salt spray, base frame with a guaranteed 1000 hours of resistance to salt spray (in accordance with the ISO 12944 standard for corrosive environment C2)

- Monthly tests for compliance with the requirements via samples provided by the suppliers

- Annual UV resistance testing

- Evaluation of resistance to corrosion and its propagation

- 100% of tanks are tested for permeability, to prevent any risk of leaks

Safety of Persons & Property

- IP64 locks, made from stainless materials

- Personal protection by protective grilles, ensuring hot and rotating parts meet the strictest standards (machinery directive 2006/42/EC)

- Electrical continuity ensured for the enclosure/base frame assembly

- Two lifting points (one on the enclosure, the second on the base frame) with generous safety coefficients to ensure safe generator handling

- Base frame height optimized to allow it to be moved safely by forklift

- Ergonomic access to allow easy maintenance and connection of the generator

- Base frame with retention to protect the environment

Approved In Line With

The Most Stringent Standards

Kohler will never compromise on the quality of its products. All its generators are tested in the lab, which is one of the only two laboratories in the world accredited for conducting tests on generators with outputs exceeding 10 kW.

- The engine – generator assemblies are designed and manufactured in ISO 9001:2015 and ISO 14001:2015 certified premises.

- Furthermore, Kohler provides and develops its activity in line with its CSR policy (Corporate Social Responsibility)

- The generators and their components are prototyped, manufactured in the factory, tested during production, and comply with all the applicable standards:

Directives

| Machinery directive | 2006/42/EC |

| Low voltage directive | 2014/35/EU |

| EMC directive | 2014/30/EU |

| Outdoor noise directive | 2000/14/EC |

Regulation

| EC regulation concerning the registration, evaluation, and authorization of chemical substances, and the restrictions applicable to these substances (REACH) | 1907/2006/EC |

Standards

General Generator Standards

| Engine power | ISO 3046-1 |

| Performance, generating set application class, application methods, etc. | ISO 8528-1 to 13 |

| Generating set safety | EN ISO 8528-13 |

| General safety principles | ISO 12100 |

| Electrical equipment of machines | IEC / EN 60204-1 |

Engine

| Exhaust gas emission measurement | ISO 8178 |

| Engine safety | EN 1679-1 |

Alternator

| Rotating electrical machines | IEC 60034 |

Electrical Equipment

| Electrical protection | IEC 60364-4-41 |

| Control gear and switch gear | ISO 8528-4 |

| Low voltage switch gear and control gear | IEC 60947-1 to 3 |

| Low voltage switch gear and control gear assemblies | EN 61439-1 |

| IP rating, enclosures for electrical equipment | IEC 60529 |

References

In Stock and Available

X-PRESS is a range of standard generators stocked across the world, which can be delivered to you within a very short lead time.

The responsiveness of the company is based on its development of 8 storage platforms which, in co-operation with the subsidiaries, constitute an efficient commercial network.

Trouble-Free Operation Guaranteed:

Quality Tests & Analyses

Each Kohler generator is manufactured, then tested in full before shipping. Our operators check its essential characteristics, such as the advertised output, and check the compliance of the product. Thousands of generators are tested each year, in line with stringent procedures which are audited twice a year as part of ISO 9001 certification. The end user can therefore be fully confident that the generator will be ready to run, whatever the output or configuration selected.

Management Quality/Safety/Environment (QSE)

Kohler deploys Quality, Safety, and Environment management systems which comply with regulations. It has made them a part of its comprehensive sustainable development and corporate social responsibility (CSR) policies. This enables it to ensure that its customers are satisfied, whilst guaranteeing the health and safety of its customers, and reducing its impact on the environment.